At Globe Metal, we specialize in unlocking the full potential of titanium scrap. With decades of expertise and a commitment to precision, we deliver high-quality titanium recycling solutions tailored to meet the exacting demands of modern industries.

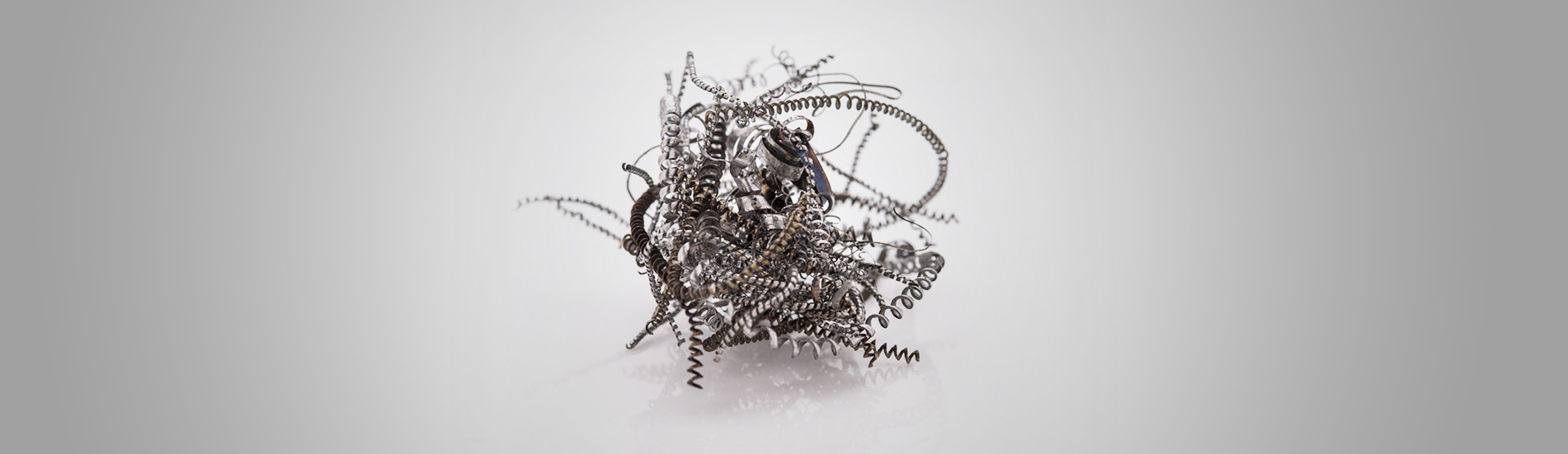

1. Advanced Sorting and Separation Techniques

Titanium scrap comes in many shapes and sizes—machining swarf, sheet offcuts, production discards, and more. The first step in our process is meticulous sorting based on quality and composition. Using advanced automated systems, we can accurately identify and separate various titanium grades from other metals, alloys, and contaminants. This critical phase ensures that only premium-grade material moves forward in the process, laying the foundation for a high-integrity end product.

2. High-Precision Cleaning and Refining

Once sorted, the titanium undergoes a comprehensive cleaning and refining process. Titanium scrap is often contaminated with oils, coatings, or other residues. Our cutting-edge methods—ranging from chemical baths to high-temperature furnaces—are designed to strip away these impurities without compromising material integrity. The result: titanium that’s purified to the highest industry standards and ready for reintroduction into demanding applications.

3. Melting and Re-Alloying

Next, the clean titanium scrap is carefully melted in high-temperature furnaces. This process removes residual impurities and prepares the material for potential re-alloying. Depending on the application, we may introduce additional alloying elements to achieve specific mechanical properties. Whether destined for aerospace, medical, or industrial use, each batch is engineered with precision—because consistency and performance are non-negotiable.

4. Rigorous Quality Control and Testing

Quality is at the heart of everything we do. Every batch of recycled titanium undergoes extensive in-house testing to ensure it meets or exceeds the industry’s highest standards. From tensile strength to corrosion resistance, our laboratory analysis guarantees that the material is not only fit for purpose—but reliable under pressure, wherever it’s used.

5. Customized Solutions for Every Client

No two clients are the same—and neither are their material requirements. That’s why we offer flexible, client-focused solutions tailored to your specifications. Whether you’re sourcing high-purity titanium for medical devices or a custom alloy for aerospace components, our team works closely with you to ensure a perfect match. We handle a wide variety of titanium grades with confidence and care, so you can focus on innovation without compromise.

Looking to purchase or recycle raw metals? Reach out to our sales team today.