In modern manufacturing, precision and reliability start long before parts are machined or components are assembled. They begin with the metals themselves. At Globe Metal, we supply certified ingots designed to meet the strictest standards of performance, durability, and traceability, ensuring manufacturers have access to the high-quality raw materials their industries demand.

Why Certified Ingots Matter

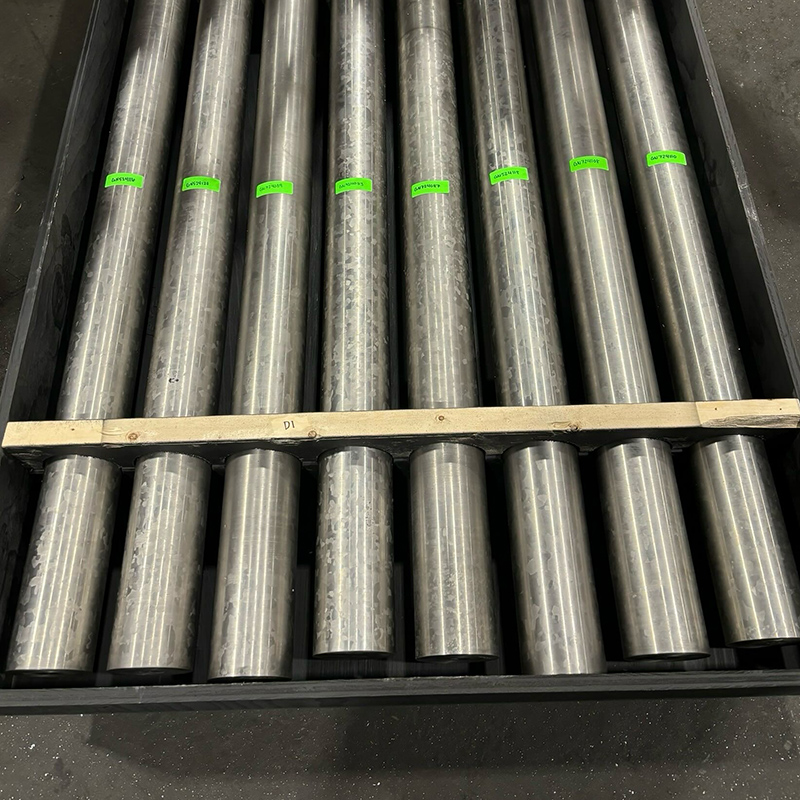

Ingots are the foundation of countless high-performance applications. They form the base material from which critical parts are cast, forged, or machined. When an industry depends on durability under extreme heat, resistance to corrosion, or exacting performance in medical or aerospace environments, the ingots themselves must deliver consistency without compromise.

Certification adds another layer of assurance. With certified ingots, manufacturers can ensure that the material’s chemistry and quality are verified, traceable, and aligned with regulatory or performance standards. That confidence enables production teams to focus on building advanced products, rather than worrying about raw inputs.

Built for Extreme Conditions

Globe Metal’s portfolio includes heat-resistant alloys such as Inconel, Hastelloy, and Waspaloy. These ingots are engineered for industries where components face punishing environments, such as jet engines, power generation, and high-temperature industrial processes. Their ability to retain strength under stress makes them indispensable for manufacturers who cannot risk variability.

For specialized applications, we supply ingots like Niobium Hafnium C-103 and Copper Beryllium, each with unique properties that meet the needs of high-tech and demanding environments. From conductivity and lightweight strength to stability in aerospace applications, these materials are trusted for critical roles where performance is everything.

Strength, Versatility, and Advanced Materials

Alongside these specialized alloys, our inventory features Cobalt Alloys and Titanium 6-4, widely recognized for their balance of strength and versatility. These metals are used extensively in aerospace and medical technologies, where precision and consistency translate directly into safety and reliability.

We also supply Super Alloys and Single Crystal Alloys, designed for some of the most demanding environments in modern engineering. These ingots resist creep, corrosion, and thermal degradation, making them essential for turbine blades, high-temperature structural parts, and next-generation manufacturing processes.

Every ingot supplied by Globe Metal is processed, graded, and traceable. This ensures manufacturers receive metals that not only meet specifications but also deliver repeatability across every lot, which is crucial in industries where consistency drives performance.

Applications Across Industries

The value of certified ingots extends across multiple sectors.

- Aerospace manufacturers rely on certified superalloys for components that must endure intense heat and pressure during flight.

- Energy producers use Inconel, Hastelloy, and Waspaloy to build turbine components and refining equipment that can withstand continuous high temperatures.

- Medical technology companies rely on titanium and cobalt alloys to manufacture implants and devices, where biocompatibility and consistency are crucial.

- Advanced industrial manufacturers rely on molybdenum and single-crystal alloys for applications that require mechanical stability and strength in extreme conditions.

In every case, certified ingots provide the raw material foundation that allows these industries to operate, innovate, and grow.

A Partner in Consistency and Innovation

At Globe Metal, our role goes beyond supplying ingots. We act as a strategic partner in production, ensuring that manufacturers have access to the exact materials needed to maintain efficiency, quality, and compliance. By delivering certified ingots that are consistent and ready for use, we help customers streamline their processes, reduce risk, and strengthen their supply chains.

Our commitment to quality ensures that every ingot we produce supports the success of our partners. Our investment in advanced processing and grading systems ensures that customers receive more than just raw metal. They receive assurance, reliability, and precision with every order.

Looking for certified ingots you can trust? Contact Globe Metal today to learn how our raw material supply solutions can support your production with dependable, high-performance metals.