Thin film coatings are at the heart of many of today’s most advanced technologies. From semiconductors and energy storage systems to aerospace and medical devices, they enable products to be smaller, faster, more efficient, and more durable. However, achieving this level of performance requires a foundational element: a reliable supply of high-quality metals engineered specifically for thin film applications.

At Globe Metal, we supply the precision metals that make these technologies possible. Each metal is processed, graded, and prepared to meet exacting standards, ensuring that manufacturers can depend on consistency and reliability in every layer of their coating systems.

Meeting the Demands of Electronics and Energy

Electronics and energy systems depend on conductivity and durability at a microscopic level. Metals such as Copper, Nickel, and Cobalt are indispensable in these applications, valued for their ability to conduct electricity efficiently while maintaining stability over time. Whether in semiconductors, batteries, or energy storage solutions, Globe Metal supplies these materials in production-ready form, helping manufacturers meet performance expectations in markets where even small variations can lead to major setbacks.

Critical Materials for Optics and Displays

For optics, displays, and other high-precision technologies, clarity and transparency matter just as much as strength. That’s why Globe Metal supplies metals like Indium, Gallium, and Zirconium, which are prized for their reflectivity, transparency, and purity. These elements play a vital role in creating thin films that improve visual clarity, durability, and overall product quality in advanced display technologies and specialty optics.

With the right materials, manufacturers can push optical technologies to new levels of resolution, efficiency, and long-term stability.

Resilience in Harsh Environments

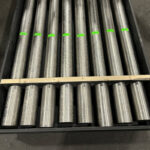

Thin films aren’t just about optics and electronics – they’re also essential in industries where conditions are extreme. Molybdenum, Tantalum, Tungsten, and Titanium are used to produce coatings that can withstand high heat, corrosion, and mechanical stress. These metals provide the resilience manufacturers need to ensure performance under the most demanding conditions, from aerospace engines to medical devices designed to function inside the human body.

By supplying these materials in production-ready form, Globe Metal ensures that manufacturers can focus on innovation, rather than uncertainty about their raw material inputs.

Supporting Innovation Through Consistency

What sets Globe Metal apart is not just the wide range of elements we supply, but the way we prepare them. Every shipment is graded and processed with precision, ensuring traceability and consistency across batches. For our customers, that means they can count on their thin film coatings performing exactly as designed, time after time.

Consistency is more than a convenience — it is the foundation that allows industries to innovate. With stable, high-quality supply from Globe Metal, manufacturers can develop new generations of electronics, energy systems, and aerospace technologies with confidence.

A Partner in Performance

At Globe Metal, we are more than suppliers of metals. We are partners in production, collaborating with manufacturers to provide materials that enhance the efficiency, reliability, and longevity of thin film technologies. Our comprehensive portfolio of elements ensures that we can meet the unique needs of various industries while maintaining the highest standards of quality and performance.

From copper to cobalt, indium to tungsten, we produce the raw materials that help our customers bring cutting-edge ideas to life.

Contact Globe Metal today to learn how our thin-film coating metals can support your most advanced manufacturing applications.