We know metals

Globe Metal® recycles metal from nearly every industry and offers its customers access to direct markets so they can maximize the value of their scrap and waste materials.

We know metals

Globe Metal® recycles metal from nearly every industry and offers its customers access to direct markets so they can maximize the value of their scrap and waste materials.

Industrial Metal Recycling

WE BUY AND SUPPLY

Antimony

Beryllium & Beryllium Alloys

Bismuth

Cobalt alloys

Gallium

Hafnium & Hafnium Alloys

Hastelloy Scrap

Haynes Scrap

High Temp & Super Alloys

INCONEL alloys

Indium

Lead

Molybdenum & Moly Alloys

Monel Scrap

Niobium & Niobium Alloys

Precious Metals

PWA alloys

Rare Earth Metals

Rene Scrap

Rhenium scrap

Tantalum & Tantalum Alloys

Tin

Titanium

Tungsten

Waspaloy Scrap

Zinc

Zirconium & Zirconium Alloys

Contact Us

ABOUT GLOBE METAL

Globe Metal. Your Go-to Industrial Metal Recycling Partner.

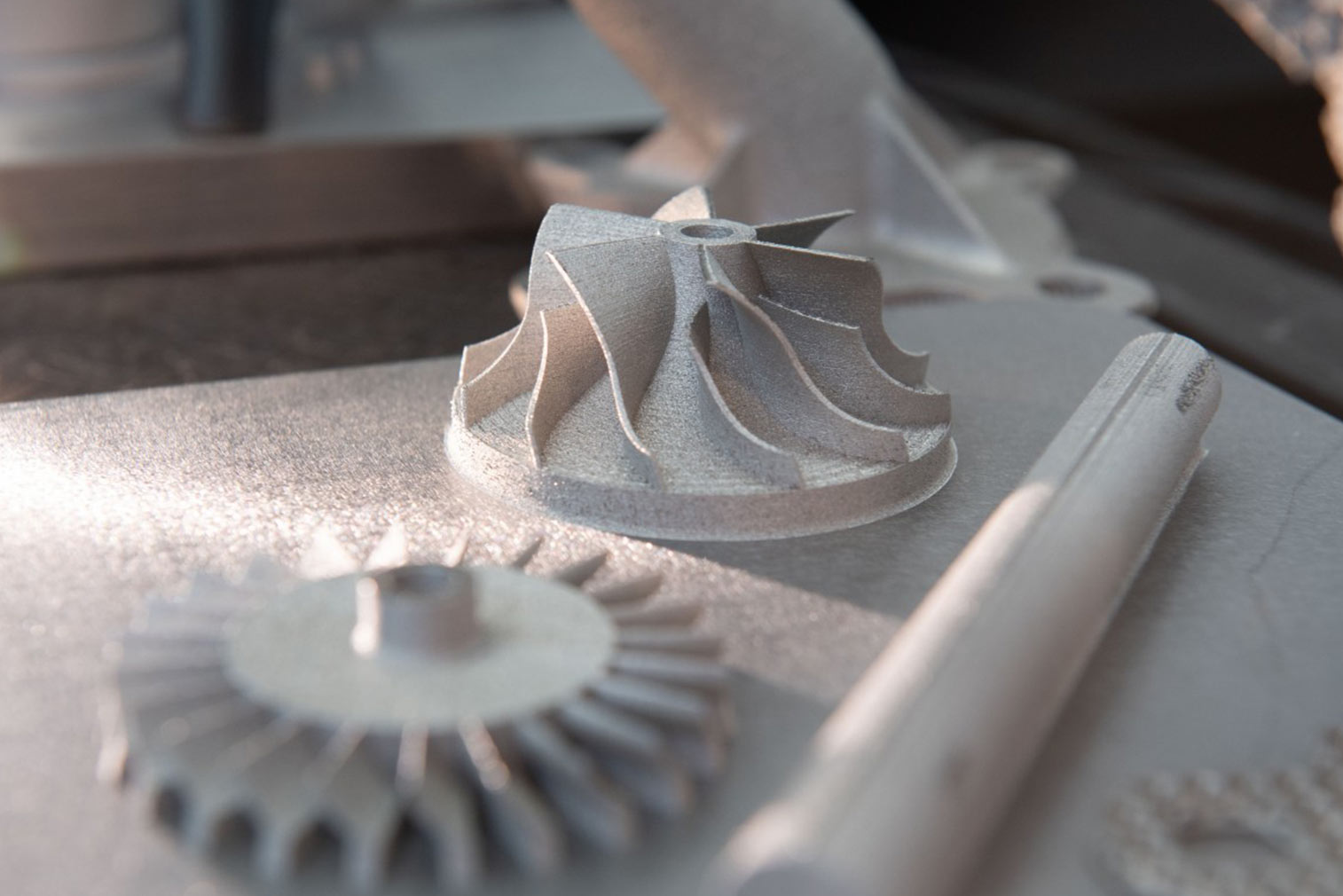

Located in Montreal and servicing North America and around the world, Globe Metal® is a top metal recycling service, specializing in molybdenum, nickel, cobalt, tungsten carbide, tantalum, spent catalyst, metal powder, high speed steel, and thermal spray. We offer our customers access to direct markets so that they can maximize the value of their scrap and waste materials in any form, including solids, turnings, chips, powder, dust, sludge, overspray, catalysts, waste, grindings, filter cake, tailings, flue dust and filters. We use industry-leading recycling processes to recover the valuable elements of each recyclable metal before we make it available to the global marketplace.

With over 40 years in the industry, we have established ourselves as the top metal recycling authority that provides unmatched knowledge of industrial metals, fair market prices, and comprehensive customer service.

For any questions about our metal recycling services, please reach out at 1-888-517-6368 or sales@globemetal.com. Ask us for a quote today.

Industrial Metal Recycling

MAJOR INDUSTRIES

Defense

Aerospace

Power

Generation

Medical

Additive

Manufacturing

And many

more…

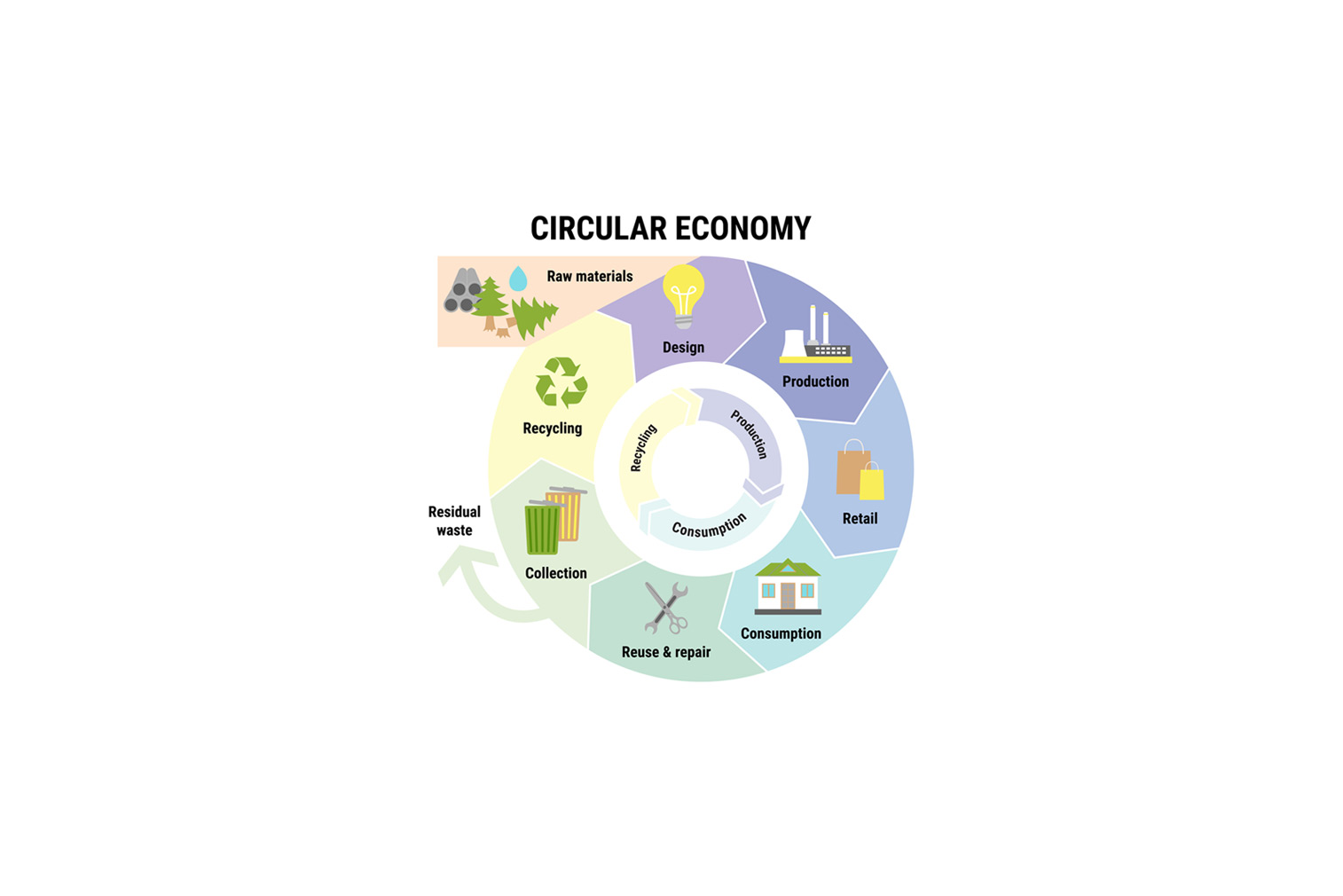

How to recycle

WITH GLOBE METAL®

Send details & sample for analysis

Receive offer and terms

Shipment of metal materials handled by Globe Metal®

In house cleaning, processing and packing

Recycle through Globe Metal®’s international network

Receive payment from metal waste, documentation and certification of recycling

Recent

BLOG POSTS